Ultimate Faraday Cage Rochester: Safeguard Your Electronics from RF Disturbance

Ultimate Faraday Cage Rochester: Safeguard Your Electronics from RF Disturbance

Blog Article

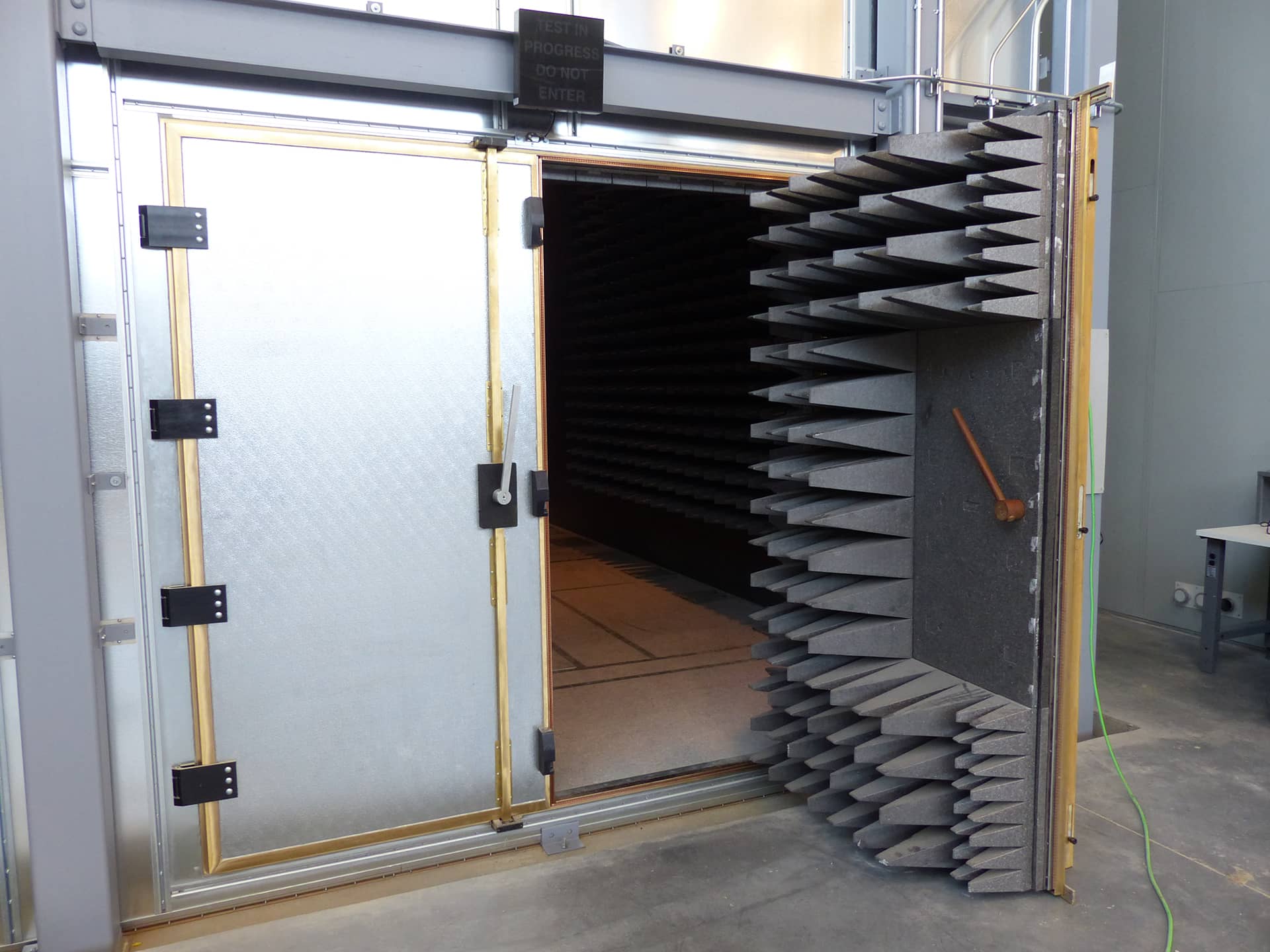

Making Best Use Of Checking Precision With Shielded Examination Rooms in Electronic Advancement Processes

Shielded test units have arised as a key device in enhancing the accuracy of screening treatments for electronic parts and devices. The application of shielded examination units extends past plain insulation, providing a myriad of advantages that add to the overall high quality and efficiency of testing results.

Importance of Protected Examination Units

The usage of secured examination units is extremely important in making certain dependable and precise digital advancement processes. Protected enclosures supply a regulated testing environment by preventing electro-magnetic disturbance (EMI) from outside resources that could compromise the integrity of electronic testing treatments. This is specifically essential in sensitive electronic measurements where even the tiniest disturbance can cause wrong outcomes. By having the electro-magnetic signals within the unit, secured test rooms help preserve the consistency and repeatability of test outcomes, inevitably boosting the total top quality of digital growth procedures.

Furthermore, shielded examination rooms add to meeting regulatory standards and conformity requirements in the electronic devices market. These enclosures assist in creating a secured area that reduces the threat of discharges that could hinder other digital gadgets or communication systems. This not just guarantees the integrity of the gadgets being tested yet also protects against any type of prospective disturbances to surrounding tools. Essentially, the relevance of protected test units hinges on their capability to secure the precision and integrity of electronic advancement processes with the development of a regulated and interference-free screening setting.

Sorts Of Secured Examination Enclosures

Various setups of protected examination units deal with varied screening requirements and specifications in electronic advancement processes. One typical kind is the benchtop secured examination unit, which is suitable and small for checking small electronic tools or components. These enclosures offer a protected setting that stops exterior disturbance throughout testing, making sure precise results. One more type is the rack-mounted shielded examination unit, which is made to fit right into typical tools shelfs. This kind of unit appropriates for bigger testing setups where multiple tools require to be checked all at once. In addition, portable shielded examination units use versatility for on-site testing or when movement is required. These enclosures are simple and lightweight to move, making them excellent for area testing or troubleshooting digital systems (rf test enclosure rochester). In general, the choice of secured test enclosure relies on the specific testing needs, the dimension of the devices being checked, and the degree of flexibility required in the digital growth procedure.

Benefits of Using Protected Enclosures

Enhancing electro-magnetic compatibility and guaranteeing reputable examination results, secured enclosures play a vital duty in preserving the stability of digital advancement processes. One of the essential advantages of utilizing protected rooms is their capability to reduce electromagnetic interference (EMI) from external sources. By providing a regulated setting with marginal exterior interference, secured rooms allow precise testing of digital tools without the danger of false results triggered by unwanted electro-magnetic signals.

In addition, protected rooms provide a high level of security by protecting against delicate info from leaking out and unapproved signals from going into the testing setting. When testing proprietary or confidential digital components that need a safe and secure screening atmosphere., this function is especially essential.

Furthermore, protected rooms aid in conforming with governing requirements and qualifications by offering a regulated testing atmosphere that fulfills the required electromagnetic compatibility (EMC) standards. This guarantees that the digital tools being evaluated will certainly fulfill the necessary market criteria for electromagnetic discharges and resistance, bring about smoother certification procedures and quicker time-to-market for items.

Factors To Consider for Shielded Room Option

In the process of choosing secured units for digital development, cautious factor to consider of environmental aspects and details demands is extremely important. The very first consideration when choosing a protected room is the product made use of for its building and construction. Conductive products such as steel or light weight aluminum are generally chosen for their protecting efficiency. Furthermore, the size of the enclosure need to be ample to suit the digital parts being examined while permitting for correct air flow and cable television administration.

Another crucial variable to think about is the level of securing needed for the testing setting. High-frequency applications may demand rooms with exceptional electromagnetic disturbance (EMI) protecting capabilities to protect against signal disturbance and ensure exact test outcomes. Additionally, the accessibility attributes of the room, such as ports, panels, and doors, ought to align with the testing needs to promote convenient accessibility to the equipment under examination.

Finally, the transportability and scalability of the shielded room needs to be assessed to make sure adaptability in accommodating future testing demands and potential reconfigurations. By thoroughly examining these factors to consider, electronic advancement procedures can take full advantage of screening precision and efficiency with the suitable protected room option.

Combination of Shielded Enclosures in Testing

The seamless combination of protected rooms right into screening treatments is important for guaranteeing precise and reputable electronic advancement processes. Shielded enclosures play a crucial duty in decreasing exterior disturbance during testing, thus boosting the precision of results. When integrating protected enclosures right into screening environments, it is essential to consider elements her comment is here such as the dimension of the unit, the kind of securing material used, and the certain testing requirements of the digital components being evaluated.

One key element of integrating shielded enclosures right into screening is making sure proper connectivity within the room. This includes establishing safe and secure connections for source of power, data transfer, and tracking devices to properly perform tests while keeping the protecting performance of the unit. Furthermore, implementing appropriate ventilation and cooling systems within the enclosure is vital to avoid overheating of electronic components during testing procedures.

Verdict

In conclusion, making use of secured examination units in electronic development processes is critical for making the most of testing precision. Different kinds of protected units provide various advantages, and cautious consideration needs to be provided to picking one of the most suitable one for details testing demands. Incorporating secured enclosures right into the testing process can dramatically improve the see this page dependability and effectiveness of digital testing treatments.

Secured rooms offer a regulated testing setting by avoiding electromagnetic disturbance (EMI) from outside resources that could jeopardize the integrity of electronic testing procedures - faraday cage rochester. By having the electro-magnetic signals within why not try here the room, shielded examination units assist keep the consistency and repeatability of examination outcomes, inevitably enhancing the overall top quality of electronic advancement processes

When incorporating shielded enclosures right into screening settings, it is vital to consider aspects such as the dimension of the unit, the kind of protecting material made use of, and the certain screening demands of the digital parts being reviewed.

One key facet of incorporating secured enclosures right into testing is guaranteeing appropriate connection within the room. Incorporating shielded rooms into the screening process can substantially boost the integrity and effectiveness of digital screening procedures.

Report this page